Industrial Laser cutting

Laser cutting is a central component of our manufacturing. We cut sheet metal precisely and quickly in dimensions of up to 16 meters.

The high performance laser cutting system offers short production times with a consistently high level of quality. The smooth and burr-free cut edges require no post-processing. This reduces costs and saves valuable time. Unlike alternative processes such as punching, laser cutting is economical viable even for small quantities. It is particularly used for high-precision production of complex forms and contours in sheet metal.

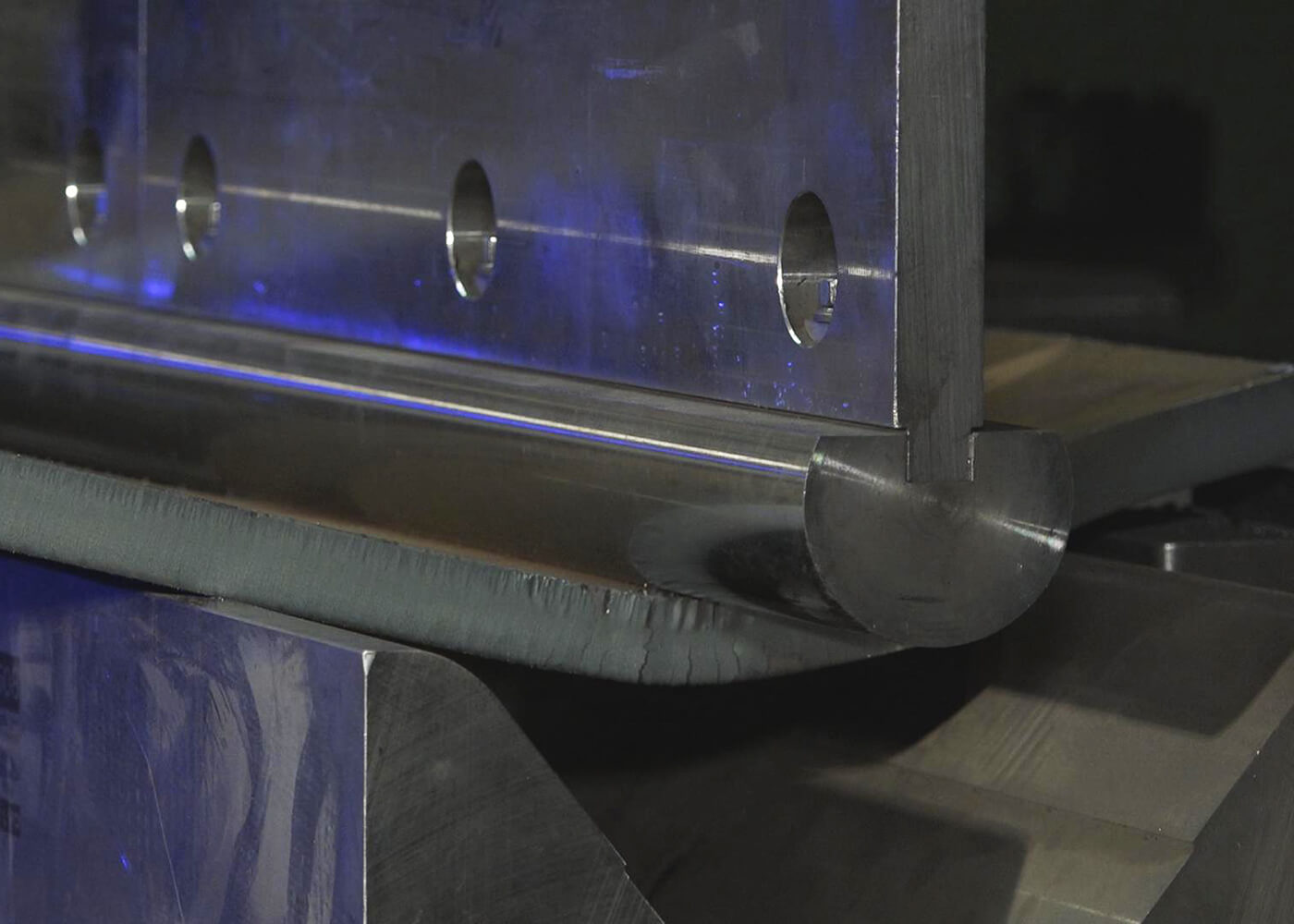

Press brake technology

Bending is an economical method for sheet metal forming. Our bending machines have a processing length of 14 meters for both large and small sheets or other filigree components.

Mechanical processing

As a metalworking shop, we turn and mill in our metal-cutting processes. We offer you custom production of special parts in steel and non-ferrous metals even in small quantities. We also include the production of samples and prototypes.

Perfect finish

Our free-jet blasting room with sand, corundum or glass beads can de-rust, matte, paint strip, descale and de-coat. The roller conveyor system and paint shop, top off, our sheet metal processing options. From economical bending to a perfect finish in the desired colour - even for large components and construction we offer the perfect finish product.